Within this section you will find

Indian Solar PV Manufacturing Overview

While this global shift has primarily been to China and Taiwan, India is also likely to see a boost in PV manufacturing with the ambitious targets under JNNSM. India already has about 3GW of solar power installations. A 33 times increase to 100 GW over the next few years is reason enough for many entrepreneurs to take a serious look at this sector.

Solar Manufacturing – Raw Material Processing

Raw material processing is required for Crystalline Silicon panels. Thin-Film panels do not have a distinct material processing stage as module manufacturing is primarily a single integrated stage.

Raw material processing for Crystalline Silicon includes

- Polysilicon

- Ingots &Wafers

- PV Cells

Polysilicon

The basic raw material for manufacturing polysilicon is silicon, which is available in plenty in the form of silicon di-oxide in sand.

- Silicon oxide sand (quartz)is processed at high temperature to separate oxygen and silicon

- The silicon obtained is purified by various technologies such as coke reduction, distillation and Siemen’s process

![]() Polysilicon manufacturing is the fundamental process in the solar PV value chain, as well as the most intricate. Investments required are high due to extensive land and equipment requirements.

Polysilicon manufacturing is the fundamental process in the solar PV value chain, as well as the most intricate. Investments required are high due to extensive land and equipment requirements.

Ingots & Wafers

The next step is ingot manufacturing where the polysilicon is melted and cast into ingots. The ingots are in different shapes and sizes; these ingots are further cut into ultrathin wafers. Wafer shaping involves a series of precise mechanical and chemical processes that are necessary to turn the ingot into a wafer.

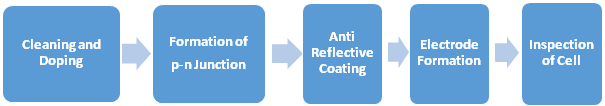

Solar Cells

The PV cells convert sunlight to electricity which is the first step in solar power generation. Solar cells form the base for the PV module and are manufactured from the wafer. The solar cell has two layers of silicon; doping is performed to form the p-n junction layer which is the basis of power generation. A layer of silicon nitride is deposited on the cell surface to reduce reflection. Electrodes and aluminium layers are added.

Crystalline cells are of two types

Crystalline cells are of two types

- Monocrystalline

- Polycrystalline

Monocrystalline Cells

The characteristic feature of monocrystalline cells are

- Higher efficiency (plant developers require less land)

- Higher cost

- Complex manufacturing process

- Requires rigid mounting to avoid cracks in the crystals during transport, handling, and installation as cells are fragile

- Uniform appearance when installed as all cells have the same dark colour

Polycrystalline Cells

The characteristic feature of polycrystalline cells are

- Lower efficiency than monocrystalline cells

- Relatively low cost

- Simpler manufacturing process

- Not uniform in appearance after installation

Solar Manufacturing – Intermediate

Glass

Glass has an important role to play in the solar energy sector. Glass is used as a top cover for all types of photovoltaic panels that include Crystalline and Thin-Film technology. The glass is typically low-iron glass to maximise transmission of light. In thin-film panels the substrate used for deposition will typically be glass (polymer is also used in some cases).

Solar Manufacturing – Finished Products

Solar Modules

Crystalline Silicon

- Crystalline silicon solar module (or panel) is the collection of solar cells soldered together under a glass pane surrounded by aluminium frame. The cells are soldered as per the required wattage. Panels are manufactured in separate plants.

Thin Film

Thin film cells are quite different from crystalline silicon cells both in terms of their characteristics and their manufacturing process.

The thin film solar modules are categorized based on the photovoltaic material deposited on the substrate

- Amorphous Silicon (a-Si)

- Cadmium Telluride (CdTe)

- Copper Indium (Gallium) di-selenide (CIS or CIGS)

The organic photovoltaic cells are emerging technology. The most commonly used semiconductor materials are CdTe and CIGS. The advantages and disadvantages for using these thin-film panels are

Table 7: Comparison of PV Material (Thin-Film)

| PV Material | Advantages | Disadvantages |

| Amorphous Silicon | Mature manufacturing technology | High equipment cost, low efficiency |

| Cadmium Telluride | Low manufacturing cost | Rigid substrate is required; considerable efficiency; toxic; less available |

| Copper Indium GalliumSelenide | High efficiency, any substrate | High manufacturing cost |

Thin-Film solar cells are formed by depositing several layers of photovoltaic material on a substrate which is generally glass or transparent film. Module manufacture is an integrated process that cannot be segregated. Thin-film modules are currently of lower efficiency than crystalline modules, limiting them to ground-mounted plants where space is not a constraint.

Inverters

Solar inverters convert the DC power generated by the panels into the AC power that can be injected into the utility/facility grid. Inverters are becomingly increasingly complex, incorporating charge controllers for battery charging regulation and remote monitoring systems.

Solar Inverters typically serve three different user segments

- Utility scale grid-tied inverters – These inverters only sync with grid power and are designed to shut down the solar plant in the event of grid failure

- Rooftop inverters – These inverters are smaller in capacity and come in a variety of configurations – some that can integrate with multiple sources of power (EB, diesel, battery) and other grid-tied inverters that work mainly with the grid power and hence do not function during power outages.

- Offgrid Inverters – A third type of inverter is the one that is used for small, off-grid solar power plants, which usually work with battery storage.

Monitoring Systems

Solar monitoring systems are gaining importance as they assist the generator to instantly know the amount of solar energy generated. They help in reducing maintenance cost and time taken for fault detection, and maximise energy generation. They can be wired (suitable for medium and large plants) and wireless (suitable for small and medium sized plants). Nowadays monitoring systems are increasingly integrated with solar inverters.

Mounting Structures

Mounting structures are necessary for any kind of solar PV installation (rooftop or ground mounted) to support the PV panels. Mounting structures are designed to enable the panels be optimally oriented to the sun for maximum energy generation. They are typically made of galvanized iron and can be elevated structures, as well as either penetrating or non-penetrating.

Balance of System

Energy acquired from solar PV system is not only reliant on the efficiency of PV module but also on other components like cables, transformers, surge protection, panel connectors, junction boxes, etc., collectively termed balance of system. Balance of system comprises all the components required for the PV System installation other than PV panels, inverters, and mounting structures.

Many components in the balance of system are commodity items that are used in various industries; there are usually many well established players in the market making it a bit difficult for new entrants, but small entrepreneurs could find a lot of contract work.

AC Cables

These cables transmit AC power from the inverter to the grid/AC distribution board. Aluminium conductors are usually used to save on cost; may be armoured for underground use.

AC Distribution Boards

Provides overload and short circuit protection on the AC side of the solar plant, standing between the inverter and the electrical loads.

AC Isolator

A disconnect switch that manually isolates the inverter from the grid supply, used during installation and maintenance

Array Junction Boxes

Solar panels are arranged into arrays of serially connected panels. These arrays (sometimes also known as strings) are connected in parallel through an array junction box from which power is fed to the inverter. Array junction boxes include safety systems like disconnects and support monitoring solutions as well.

Batteries

Usually used only with rooftop solar plants, batteries allow solar power to be stored and used at a more convenient time, such as at night or when electricity tariffs are very high (for consumer who have time-of-day tariffs).

Connectors

Connectors are used to link cables together e.g., when connecting solar panels in series to form an array. Connectors need to confirm to various standards and specifications both for reasons of safety and to ensure that only authorised personnel can disconnect parts of the plant.

DC Cables

These cables transmit DC power from the panels to the inverter, charge controllers to battery, and battery to inverter. Copper conductors are usually used.

DC Distribution Boards

Provides overload and short circuit protection on the DC side of the solar plant, standing between the panels, batteries, and inverter. Usually includes a meter to monitor current flow.

Disconnects/switches

A solar plant requires many switches that can isolate specific parts of the circuit for safety and maintenance.

Earthing Kit

Solar plants require separate DC and AC earthing with multiple earth pits required for even small plants.

Fuses

A solar power plant is an electrical system with heavy current and high voltages. Multiple fuses are used to protect personnel and equipment.

Lightning Protection

Solar plants are susceptible to lightning strikes and need to be protected from lightning. Even medium-sized rooftop plants require lightning protection, and large ground mounted plants require multiple lightning protection systems.

Meters

A meter measures the flow of electrical current. A solar plant uses many meters at various points either for monitoring or billing. Some meters may be government mandated and therefore suppliers will need to be empanelled with the relevant authority.

Surge Protection Devices

These protect the solar equipment from excess voltage, such as from lightning strikes.

Trackers

These allow the panels to track the movement of the sun, resulting in greater generation. They are or two types

- Single-axis – Only tracks the East-West movement of the sun through the day

- Dual-axis –Tracks daily East-West movement as well as seasonal North-South movement

![]()

Transformers

Transformers are used to step up/down voltages. Stand-alone transformers (as against transformers integrated into an inverter) are particularly used in utility scale power plants to connect the solar plant to the grid.

Related Articles

1. Business Opportunities in Solar PV Components

2. Solar Business Opportunities – An Overview

3. List of High Potential Sectors and Opportunities in the Solar Sector

4. Business Opportunities in Solar Thermal – Heating Applications

5. Business Opportunities in Solar Thermal – Power Applications

6. Business Opportunities in Diverse Off-grid Applications

7. Innovations and Niche Opportunities in Solar Power Sector

8. Ways to Identify Other Potential and Attractive Off-grid Segments

9. Attractive Segments and Innovations in Rooftop Solar Sector

10. Business Models for MW Scale Solar PV in India

11. Emerging Opportunities in Solar Thermal – Refrigeration & Air-Conditioning

12. Key Customer Segments for MW Scale Power Plants

Skip to content

Skip to content