Summary: Polysilicon, a highly refined form of silicon, is the starting material for solar cells.

For silicon-based solar cells, polysilicon is the starting material. What is polysilicon, and how is a silicon cell made from polysilicon?

Polysilicon is formed from Quartzite, a form of quartz sandstone rock. For simplicity sake, you could consider quartzite as comprising pure sand.

Owing to its excellent semiconductor properties, polysilicon is used as feedstock for solar, and is the initial building block for manufacturing silicon based Solar PV cells.

Due to its semiconductor properties, polysilicon is used as feedstock for solar, and is the initial building block for manufacturing silicon based Solar PV cells.

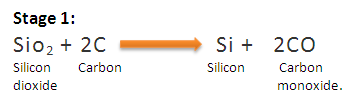

The first stage to make polysilicon is to react SiO2 (in the form of quartzite) and Carbon in an arc furnace. This results in metallurgical grade silicon (MG Silicon).

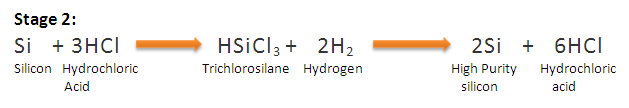

This MG silicon is then treated with HCl (hydrochloric acid) to form the compound Trichlorosilane (HSiCl3). When Trichlorosilane is reacted with hydrogen, we get high purity polysilicon and HCl. The HCl is sent back for the reaction with further additions of MG Silicon.

The purity of polysilicon used for solar cells is very high, about 99.999% or higher!

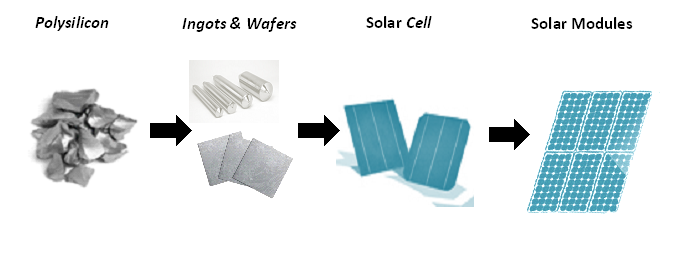

The pure polysilicon thus formed is first converted into ingots (a solid, brick-like material). These ingots are further cut into thin wafers by specially designed saws. The wafers are then fabricated into solar cells.

Questions from the curious cat

What is the starting material for polysilicon?

The starting point for pure silicon is quartzite, a fine to median grain rock comprising pure quartz sand. Quartzite contains 90-99% quartz, and as you might know, quartz has the highest concentration of pure silica of any known mineral.

What is the cost of polysilicon?

The answer to this question will vary significantly based on the year you are referring to. As of mid 2014, the price of polysilicon is about $20 per Kg. You will be intrigued to know that the price of the same material, not long ago (mid 2008), was $450/Kg.

Life is lived on skinny branches for some, isn’t it?

Is the polysilicon used for solar cells the same as the one used for making computer chips?

Yes, it is. But the purity of polysilicon required for IC circuits is much higher (99.999999%) when compared to that used for solar cells, for which it is a measly 99.9999% pure!

Can anyone set up a polysilicon manufacturing plant?

Yes, anyone can, if they can pump in over $1 billion, because that is how much it will cost to set up an economical size poysilicon plant today.

Why did the price of polysilicon fall drastically fom $450/Kg to less than $25 per Kg between 2008 and 2014?

Search me for an answer.

Seriously, we think the question should actually be: why did the price of polysilicon grow from about $60 /Kg in 2005 to $450 in 2008. It happened mainly because of a temporary shortfall in supply of polysilicon, just when the solar PV industry was beginning to grow rapidly. This temporary imbalance between demand and supply was soon taken care of, and prices started falling back to more civilized zones by 2010, and by 2014 had gone below $25/Kg, much lower than what they were in 2005!

Some interesting videos for you

A pretty good video on polysilicon manufacturing process by Wacker

Skip to content

Skip to content