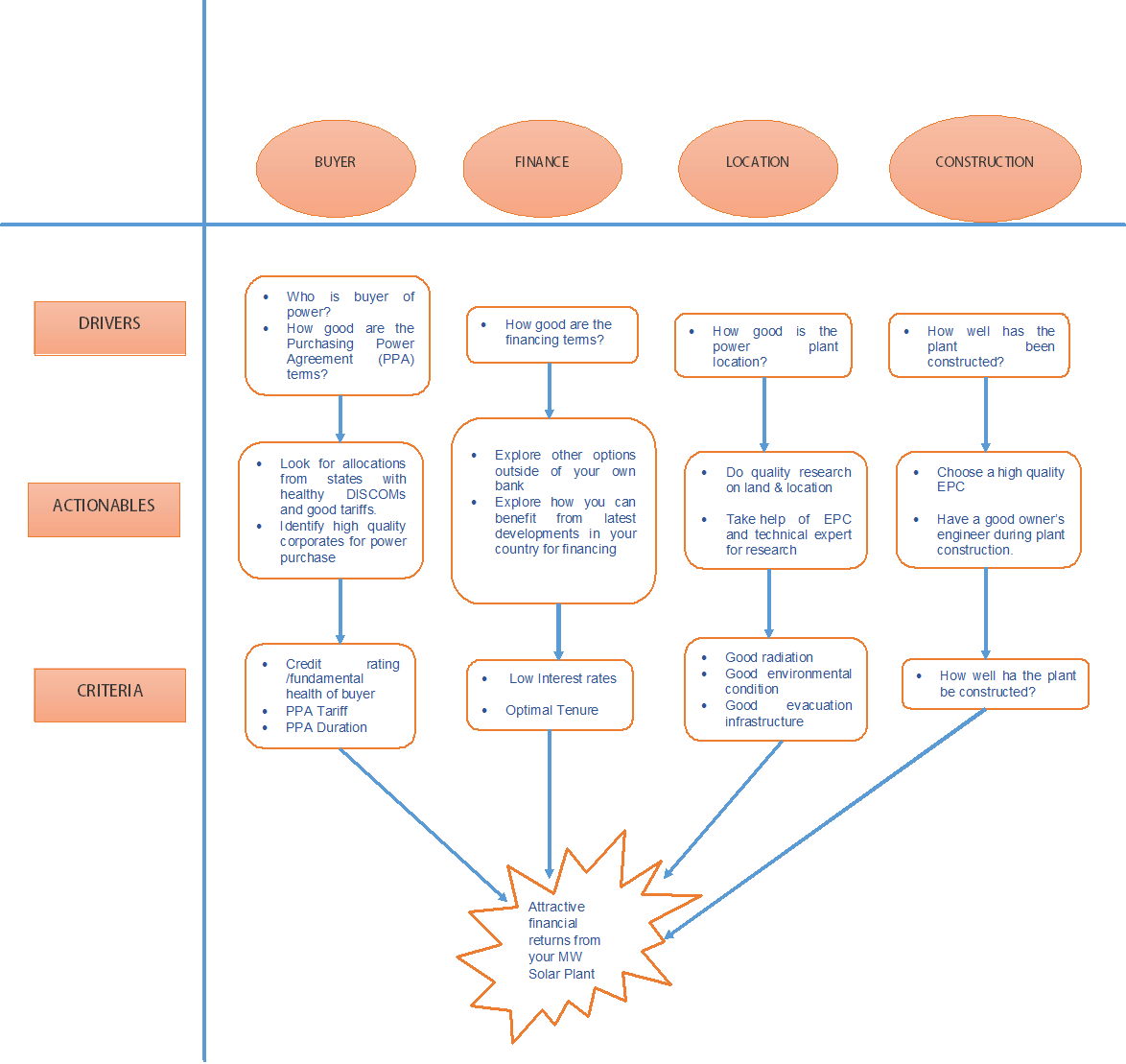

Implementing MW Solar Power Plants – Action Framework

Large, ground-connected solar power plants require significant investments. The main monetization from the MW solar power plants is either through the sale of power or savings accrued from captive power generation. While availability or ownership of land are important, these are not the most critical factors determining the success of ground mounted solar farms. The framework below provides more details on the key drivers and actionable for implementing MW solar power plants.

Step 1: Getting a PPA for a MW Solar Power Plant:

PPA A solar Power Purchase Agreement (PPA) is an agreement between a solar power generator (developer) and an energy consumer or utility (off-taker) to buy the solar power generated by the developer. In many countries, PPA contractual terms last for 25 years. It is during this time the power purchaser buys energy. Solar Developers are able to competitively price solar power for both public as well as private customers under the terms of the PPA. PPAs usually include terms of agreement i.e. details on interfacing and evacuation facilities, operation and maintenance, metering arrangements, scheduling of solar power, rate of energy including escalation rates, dispute settlement, billing and payment The PPA should specify the tariff (cents/kWh or equivalent) and the duration for which it will apply.

Challenges associated with Government/Utility PPAs:

- Tariffs may be overturned by Regulatory Commissions with time

- Poor financial health of DISCOM might lead to delay in payments to developer

- Generally speaking, government PPAs are regarded as low(er) risk as they are backed by the government and are usually signed for the duration of plant life (25 years)

Challenges associated with 3rd Party PPAs:

- 3rd Party’s financial health may be better than DISCOM’s, but long-term business prospects need to be evaluated

- Credit rating of the 3rd party should be considered as they are not backed by a government

- PPAs need not be signed for 25 years. Some are signed for as short as 3 years, leaving future revenue generation of the plant in doubt

Steps to follow to get a PPA for a MW Solar Power Plant:

- Identify potential locations :

Identify approximate area available for PV installation including any potential shading. The areas may be either on rooftops or on the ground. A general guideline for solar installations is 5–10 watts (W) per square foot of usable rooftop or other space.

- Identify potential solar policies applicable for the land :

State policies differ from region to region. The tariff rates at which PPAs are signed differ region to region. Hence zero in on a policy that can bag you a PPA that ensures profitable returns.

- Respond to the Request for Proposal (RfP) or win bids issued by the Power Purchaser:

The developer may have to respond to RfPs or win bids issued by the Third Party Power Purchaser or the Utility.

- Contract Development:

After a winning bid is selected, the contracts must be negotiated—this is a time-sensitive process. In addition to the PPA between the government agency and the system owner, there will be a lease or easement specifying terms for access to the property (both for construction and maintenance). REC(Renewable Energy Certificate) sales may be included in the PPA or as an annex to it.

- Permitting and Rebate Processing:

The system owner (developer) will usually be responsible for filing permits and rebates in a timely manner. However, the government agency should note filing deadlines for state-level incentives because there may be limited windows or auction processes.

- Project Implementation and Commissioning:

The developer should complete a detailed design based on the term sheet and more precise measurements; it will then procure, install, and commission the solar PV equipment. The commissioning step certifies interconnection with the utility and permits system startup. Once again, this needs to be done within the timing determined by the state incentives. Failure to meet the deadlines may result in forfeiture of benefits, which will likely change the electricity price to the government agency in the contract. The PPAs usually establish realistic developer responsibilities along with a process for determining monetary damages for failure to perform.

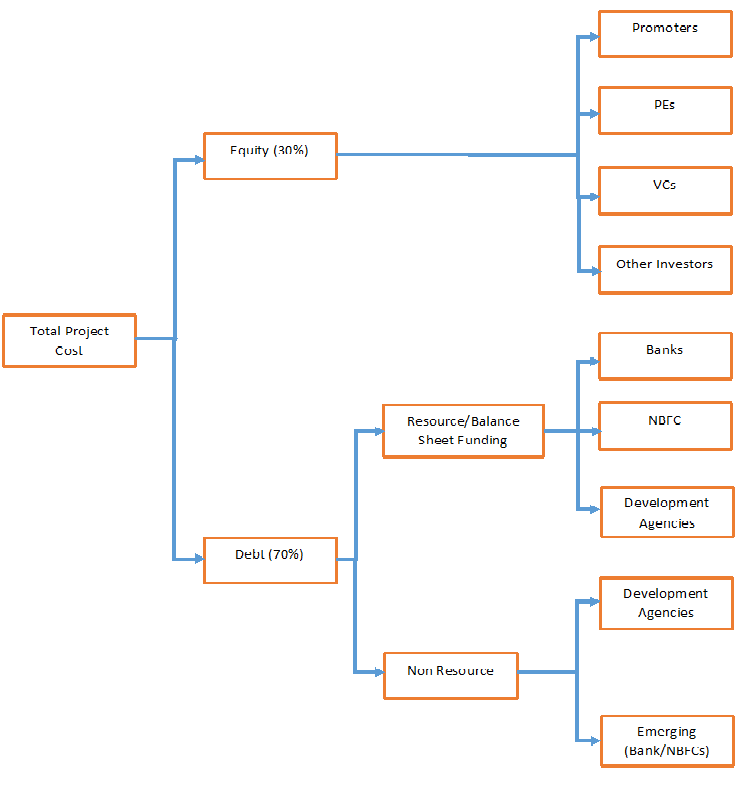

Step 2: Financing Options for a MW Solar Power Plant

A general schematic of financing options for MW Solar Power Plants is shown below:

Constraints and Challenges for Getting Financial Closure for MW Solar Power Plants

- The following are the big list of key Issues/challenges in Solar PV Financing as suggested by a range of stakeholders

- Financial Health of utilities may cause non-payment or delayed payment

- With reverse bidding, compromise in quality for cost cutting

- Delay in land acquisition

- Delay in Power Evacuation facility (ROW, Projects Cluster & Feasibility)

- Non- availability of stable grid below 66KV

- Lack of established best practices of O&M Manuals

- Trend of not opting for third-party EPC Contracts

- Wide variations in costs of PV Modules

- More time taken for obtaining important clearances, such as for NA, PCB, evacuation, etc.

- Inadequate Irradiance Data of Project Sites

- Lack of RPO enforcement, and As a Result, Lack of Demand for RECs

Suggestions to overcome the constraints in getting a financial closure:

- Solar resource assessment based on ground data for at least one year period

- Generation projections to be realistic considering project site specific parameters

- Pooling stations & evacuation facilities for clustered projects

- All clearances/approvals including land acquisition, contracts, suppliers, vendors etc. to be ready for faster financial closure

- Adopt Modular Design to maximize yield & ease of construction and also based on PPA/Policy

- Evaluation of Past performance record /downtime of off-take substation

- All contracts including supply/EPC/ O&M should be structured for proper guarantees/warranties

- Strict compliance of RPO will ensure more projects under REC.

- Exchange of actual project performance among the stakeholders/banks

- Establishment of online performance database in all the respective SLDCs of the states

- Establishment of proper Solar parks with all approvals/clearances/amenities etc. to optimize costs

- Projection of RPO of all the obligated entities and their achievement to be put in public domain

- To encourage REC projects, a trajectory beyond 2017 may be devised by Forum of Regulators

Step 3: Site Selection For a MW Solar Power Plant

Selecting a suitable site is a crucial part of developing a viable solar PV project. In selecting a site, the aim is to maximize output and minimize cost.

The main constraints that need to be assessed include:

- Solar resource – Global Horizontal Irradiation, DNI –Direct Normal Irradiance, annual and inter-annual variation, impact of shading.

- Local climate – flooding, high winds, snow and extreme temperatures

- Available area – area required for different module technologies, access requirements, pitch angle and minimising inter-row shading. The land required for a 1 MW power plant setup is around 4.5-5 acres for crystalline technology and around 6.5-7.5 acres for Thin-Film technology. This is only a rough benchmark and may vary based on technology and efficiency of panels.

- Land use/cost– this will impact land cost and environmental sensitivity. The impact of other land users on the site should also be considered. Land for solar power plants is usually located far from populated regions, low cost real estate. Depending on the location, this could be slightly less or more.

- Topography – flat or slightly south facing slopes are preferable for projects in the northern hemisphere.

- Soil type –Flat land with firm soil is better. Inclined land or loose soil could create challenges. Loose Soil could mean a lot of dust.

- Geotechnical – including consideration of groundwater, resistivity, load bearing properties, soil pH levels and seismic risk. It is a good idea to undertake Geotechnical survey.

- Accessibility – proximity to existing roads, extent of new roads required.

- Grid connection – cost, timescales, capacity, proximity and availability.

- Radiation: Your location determines the amount of solar insolation (sunlight falling on the panel per day).Overall, the location of the rooftop is by far the most important factor that determines the solar power plant output. Location determines the DNI (Direct Normal Irradiance). DNI at a location is the amount of solar energy falling per sqm per day at the location. The DNI for a sunny region is approximately 6kWh/m2/day. This is the amount of sunlight energy falling on a square meter every day in a good location. The higher the DNI, the higher the electricity produced by a solar cell.

Some inputs on DNI:- While many installations in sunny locations such as California or parts of India are able to generate 4.5-5 kWh/kW/day, the output from colder regions in Germany and elsewhere have reported 3.5 kWh/kW/day or less. Ironically, Germany, a leading country in rooftop solar installations receives much less than 4kWh/kW/day for most of its installations.

- The approximate solar insolation at your location can be ascertained by entering the latitude and longitude of your location NASA website

- To be absolutely certain of DNI at a particular site we would have to place sensors on-site that measure the actual insolation received over a period if tune, This is both an expensive and time consuming process.

- Water availability – a reliable supply is required for module cleaning.

- Soil Testing– Once the site has been selected, it is essential that the soil testing of the land is done. In sandy soil, the pile foundations for the mounting structures will have to go deeper thus escalating the costs. Rocky soil conditions are unsuitable for erecting solar structures and has to be worked on. The conditions of the soil have to be tested and is usually sub- contracted to chosen EPCs or a third-party.

- Land Levelling– The land may have bushes and other vegetation that will have to be hacked off by dozing. In some situations there may be ups and downs on the land which may require heavy land clearing equipment to complete the job. The areas for cut and fill has to be outlined and equipments like grader, bulldozers and scrapers will be used to prepare the site. Depending on the land, this can add significantly to the total project cost. Similar to soil testing, this is usually sub- contracted to chosen EPCs or a third-party.

Step 6: EPC Selection for a MW Solar Plant

EPCs are key players in implementing large solar farms as they put together all the three aspects for a solar farm – the design, material procurement and construction. It is hence critical that you choose your EPC with care.

Criteria to Choose EPCs In order to get clarity on how to choose EPCs, it will be instructive to first understand the Solar EPC Operational Value Chain.The following chain describes the various key components of value addition in a solar EPC operational chain:

Design ==> Approvals ==> Material Supply ==> Excavation & Construction ==> Mounting of Structures ==> Mounting of PV Panels & Electrical Wiring ==> Installation of Inverters and Substations ==> Testing and Connecting to Grid

The first aspect you should consider is to ensure that the EPC you choose should have expertise that covers all components of the above value chain. The EPC might not have all the skill sets in his core team, but should be able to show partnerships that have the capabilities the core team does not.

Three Types of EPCs You Should Avoid:

- Do not go for lowest cost

- Do not go for EPCs who are unwilling to involve you in decision making for key aspects of the project

- Do not go for EPCs who are not willing to introduce you to their key core and extended team members.

Key Parameters for EPC Selection

Top 5 Criteria

- The EPC contractor essentially guarantees completion of the plant on time and cost, and also plant performance, thus enabling the project developer to avail finance from their banking partners. Thus a thorough evaluation of the EPC is required before a choice is made.

- Their corporate background and earlier work background; number of years they have been in this field

- Case studies of the projects they have implemented

- Team composition, and technical/engineering skills of the key professionals in their team and strategic partnerships for technology

- Their technology/module/inverter supply partners

- Financial strength of the EPC or the parent company to which the EPC belongs

Other Criteria

- Tie-ups with financial institutions

- Accreditations

- Sub-contractors they work with

- Project management and O&M skills – an EPC with good O&M skills can also then continue to maintain and operate the plant for you

- Flexibility; also, experience of working under different conditions – geographies, terrains, timeframes.

- Other Value-adds

Specific Expertise to look for in the core engineering team of the EPC:

- Design for PV Panels

- Inverter Selection

- Electrical Design

- Civil & Structure Design

- Design for Power Evacuation

- Modules

- Inverters

- Other BoS – AC & DC Side Electricals, Cables, Monitoring Systems

- Project Management

- Government Liaising

- Others

EPC should be able to clearly explain how monitoring and control systems will be implemented, and how much O&M will be required.

- Justification for Inverter based/3rd Party solution

- SCADA implementation experience

- Evaluation of maintenance required based on site conditions

- Estimation of requirement of manpower, water, etc.

Few additional points to be regarded after the decision regarding the EPC is taken:

- While finalising the agreement with the EPC, the developer should make sure the roles and responsibilities of the developer and the EPC are clearly defined in the agreement.

- For example, storage rooms and water supply for the power plant during its construction normally comes within the scope of the developer. He must make provisions for the above. In some cases the develop may have to provide a bore well at the site for meeting the water requirements

- Similarly the access roads and power to be provided during the plant construction comes within the developer’s scope. In most cases, the auxiliary power consumption for the plant is met by the usage of a Diesel Generator. The additional costs for these add-ons must be anticipated by the developer.

- In most cases, the approvals and liaising with the nearest substation regarding the set-up of the transmission lines for grid extension may prove to be a headache for the developer. Early moves regarding these may cut back the delay which can be faced in setting up the power plant.

Step 7: Design and Construction of the MW Solar Power Plant:

The following video will help the developer gain a better understanding of the working of a MW Solar Power Plant:

Once the EPC has been selected and the agreement has been reached between the developer and the EPC, it is the responsibility of the EPC to put up the MW Solar Power Plant in accordance with the terms and conditions of the agreement.

It is always advisable for the developer to know about the different areas of putting up a MW Scale Solar Plant.

Solar Mango has provided below descriptions of different areas of the construction of the plant:

Designing and Construction

The design of a PV plant involves a series of compromises aimed at achieving the lowest possible levelised cost of electricity. Choosing the correct technology is of central importance. Selecting a module requires assessment of a complex range of variables. The factors to consider when selecting inverters include compatibility with module technology, compliance with grid code and other applicable regulations, inverter-based layout, reliability, system availability, serviceability, modularity, telemetry requirements, inverter locations, quality and cost.

In designing the site layout, the following aspects are important:

- Choosing row spacing to reduce inter-row shading and associated shading losses

- Choosing the layout to minimize cable runs and associated electrical losses

- Allowing sufficient distance between rows to allow access for maintenance purposes

- Choosing a tilt angle that optimizes the annual energy yield according to the latitude of the site and the annual distribution of solar resource

- Orientating the modules to face a direction that yields the maximum annual revenue from power production. In the northern hemisphere, this will usually be true south.

The electrical design of a PV project can be split into the DC and AC systems.

The DC system comprises the following:

- Array(s) of PV modules

- Inverters

- DC cabling

- DC connectors

- Junction boxes/combiners

- Disconnects/switches

- Protection devices

- Earthing

The AC system includes:

- AC cabling

- Switchgear

- Transformers

- Substation

- Earthing and surge protection

In order to achieve a high performance PV plant, the incorporation of automatic data acquisition and monitoring technology is essential. This allows the yield of the plant to be monitored and compared with calculations made from solar irradiation data to raise warnings on a daily basis if there is a shortfall. Faults can then be detected and rectified before they have an appreciable effect on production.

Construction:

The management of the construction phase of a solar PV project should be in accordance with construction management best practice. The aim should be to construct the project to the required level of quality within the time and cost deadlines. During construction, the environmental impact of the project as well as the health and safety issues of the workforce (and other affected people) should also be carefully managed.

- Typical issues that arise during the construction of a PV project include:

- Foundations not being suited to ground conditions.

- Discovery of hazardous / contaminated substances during excavation.

- Incorrect orientation of modules.

- Insufficient cross-bracing on mounting structures.

- Incorrect use of torque wrenches.

- Damaging cables during construction / installation.

- Delayed grid connection.

- Access / construction constrained by weather.

- Insufficient clearance between rows for vehicle access.

Step 8: Decision regarding Owner’s Engineer and O&M

Owner’s Engineer

Owner’s Engineer or Client’s Engineer is a term often given to the representative of a commissioning company of a construction or engineering project. It refers to the personnel involved in technical Due Diligence, which the developer may not have. Most often, an Owner’s Engineer is an independent third party or subcontracted role; undertaken to ensure that the technical and solar power plant build contractors are adhering sufficiently to the project specification. Owner’s Engineers also fills gaps in resources and expertise for a project.

Owner’s engineering services are important to ensure smooth and safe project development. And in the case of disputes between the developer and the chosen EPC, a technical evaluation by independent engineers offers better leverage. Hence it would be a wise investment for a developer to invest in one in order to ensure optimal performance of the plant.

O&M Requirements

Compared to most other technologies, Solar Power Plants have low maintenance and servicing requirements. However, suitable maintenance of the plant is required to optimise the performance of the plant. The usual trend regarding O&M is that the work is contracted to the EPCs itself. This is done so that the O&M Engineer is already familiar with the design and construction of the solar plant and most EPCs offers the first year operations and maintenance requirements for free.

Step 9: Commissioning of the Plant

Commissioning of the plant is the final step regarding the MW Solar Power Plant. The developer has to do this step to prove that the plant erected is structurally and electrically safe and also to ensure that the plant operates as expected.

Commissioning test are normally split into three groups:

- Visual acceptance tests: The tests are done before the plant is energised and consists of a detailed visual inspection of the plant

- Pre-connection acceptance tests: These tests are done to ensure that the voltage levels and current levels and the design of the plant is accurate. This is done before the plant is connected to the grid.

- Post-connection acceptance test: Once the plant is connected to the grid, a DC current test is done to ensure the safe operation of the plant. The performance ratio is then evaluated and compared against the expected value.

Skip to content

Skip to content