Updated September 2014

Within this section you will find

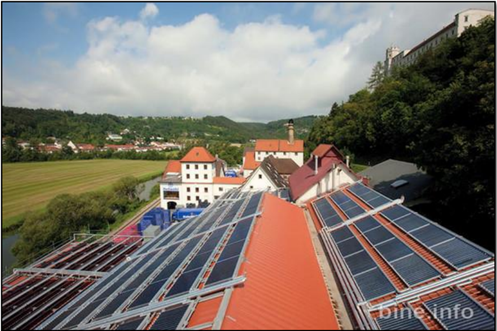

Solar for factories

Factories can include multiple processes under one roof, like manufacturing, assembling, packing, repairing, maintaining, testing, processing, storing etc. Factories typically consume both electricity and heat energy, and consume a great deal of diesel for power generation. Solar PV can help abate your diesel power bills, and in some cases even grid consumption depending on your power tariff. The energy consumption pattern varies for each type of factory with respect to the processes and requirements.Solar energy for factories can be taken from two different perspectives:

- Use of solar PV panels to meet the electricity requirements of the factory

- Employment of a solar thermal system to satisfy the heat required for the factory

Let us consider the 2 scenarios now:

Solar PV for factories

Solar powered factories typically have a rooftop space which can be allocated for the installation of solar PV panels. It can meet a percentage of the electricity requirements of the factory. Solar electricity provides added value especially in the case of factories as it can offset peak consumption. The purpose of setting up the panels on the rooftop is that it avoids the requirement of additional land. Let us look at some cases where PV panels have been employed in factories.

- ABB factory in Helsinki, Finland

Salient features

- Capacity – 181 KW

- Electricity generated – 467 MWh

- Purpose – Charging the batteries used for forklift trucks and cutting energy consumption peaks

- Total Area – 1200 Sq. Meter

- Inverters – One 120 KW ABB central inverter and ABB string inverters in the 4-8 KW range

One important feature of this installation is that it uses string inverters to offset any irregularities in solar generation caused by shading occurrences on the roof.

- Burder Industries manufacturing facility in Victoria, Australia

Burder Industries is a regional manufacturer of customized tractor and earthmoving equipment for the agricultural industry. They deployed solar as a solution to reduce its operating costs in order to stay in competition with other players.

Salient Features

- Capacity – 355 KWp

- Purpose – provides 90% of daily energy consumption, reducing around 70% of operating costs thereby improving competitiveness

- Panels used – Yingli Solar

- No of panels used – 1420

- Expected IRR from the investment – above 25%

For more details on the installation, please refer the following link:http://www.manmonthly.com.au/news/burder-industries-raises-competitiveness-of-manufa

Solar Thermal for factories

Currently, when we talk about solar powered factories, the talk is about using solar PV panels, whether it be rooftop or ground-mounted, focusing on the electricity generation aspect. But factories consume a lot of energy in the form of heat . Especially in the case of applications like smelting of metals, processing of chemicals and HVAC systems within factories, solar thermal heat can be used directly instead of utilizing the electricity supplied by PV panels.

Some examples of solar thermal installations are given below:

- Purple Creations, a children’s clothing factory at Baramati Hi-Tech Textile Park, Maharashtra

A concentrating solar thermal plant was employed at Purple Creations to provide steam to iron clothes after stitching. A burning LPG was replaced and made way for the solar thermal plant thus contributing significantly to emission reductions.

Salient Features

| Solar system | 30 dish concentrators |

| Application | Steam pressing and washing |

| LPG saved | 15 tons per year |

| CO2 emissions saved | 45 tons per year |

| Payback period | Around 5 years |

| Subsidy Availed | 30% of capital investment |

Salient Features

| Solar system | Vacuum tube collectors with parabolic reflectors |

| Application | heating water for brewing process, cleaning bottles, space heating |

Now, let us discuss the advantages and constraints of setting up solar powered factories.

Advantages

- Energy security –Rooftop solar plants can deliver power during load-shedding, ensuring that critical loads are always running. Not all solar plant configurations can deliver power during load-shedding. More details here

- Cost-effective –Rooftop solar power has a levelized cost of Rs. 4.5-5/kWh (or less), considerably lower than diesel power cost at Rs. 18/kWh (or more). Additionally, your energy cost is now fixed for the next 25 years, unlike diesel power which keeps increasing. Moreover, you are also saving on the electricity that you use from the grid which is usually priced at a higher rate

- Reliable – A solar power plant is a low risk investment, ensuring reliable power over 25 years provided quality components are chosen for the installation

- Minimal maintenance –A solar power plant has no moving parts and hence requires very little maintenance from the energy consumer

- Flexible configurations –Solar panels can be installed on different kinds of roofs, including covered parking areas, as long as the structure can bear the weight of the panels. They are also highly scalable, with rooftop plants ranging in capacity from less than 1 kW to more than 1 MW

Constraints

- Rooftop space –The capacity of the solar plant that can be installed in a factory may be constrained by lack of sufficient shadow-free rooftop space. Many factories have north light roofing special mounting structures may be required to mount the solar panels

- Roof requirements are discussed in detail here; a rule of thumb is that you will need about 100 SF of shade-free roof area for 1 kW of solar panels. Insufficient roof area will mean that the capacity of the solar plant on your roof may be sufficient to meet only part of your electrical load

- Roof type – Solar panels can be easily installed on concrete roofs, but metal and asbestos roofed structures may present some challenges, depending on the load-bearing capacity of the roof

- Infirm power –Solar power is dependent on the sun shining, and output varies depending on meteorological conditions e.g., passing clouds can temporarily reduce the solar plant’s output. Therefore night time applications will require other sources of power, or power from batteries charged through. Hence, solar power for critical equipment should be used in conjunction with another source of power

- Load-shedding timings – This may be an issue in some factories: if most of your load-shedding occurs at night, solar power may not help in reducing your diesel consumption as it is available only during the day. If possible, some of your loads may be shifted to daytime to take advantage of solar power, after considering time-of-day tariff (if any)

- Inverter weight –The DC power output from the solar panels needs to be converted to AC via an inverter which can be very heavy: a 100 kW inverter will weigh about 1,000 Kgs but occupy only a few square feet of space. If the construction cannot support this weight the inverter may need to be placed on the ground floor, with appropriate cables chosen to compensate for energy loss.

Typical Load

As the available space (rooftop or ground) may not be sufficient to support the entire electrical load of your facility with solar, it becomes necessary to estimate the different kinds of loads to identify loads that can be/need to be supported by solar.

Electrical loads are estimated by calculating the wattage or amperage of electrical equipment in use (as shown here), which can be further classified as light loads and heavier loads, with solar being used to support the light loads.

Typical electrical loads in a factory include

- Fans and Pumps

- Manufacturing Machinery (varies based on factory)

- Lighting

- Processing Equipment (welding, etc.)

- Motors

- Air Compressors

- Air Conditioners

- Computers

- Refrigeration

- Other electrical equipment

Manufacturing and processing equipment typically account for almost half the electrical load in the factory.

Our Recommendation

While some factories require niche solutions based on the products they produce, Solar Mango’s recommendations for most factories are

Alternative 1 – Grid-interactive configuration where solar power is supplied in conjunction with EB or diesel power. Here the rooftop solar plant serves to reduce diesel bills by supporting part of the overall load

- Hybrid inverter –A rooftop solar PV system that utilizes a hybrid inverter allows the solar plant to integrate with a diesel generator in addition to the utility grid.

- Integrating a rooftop solar plant with a diesel generator involves several challenges (discussed here) that need to be overcome with careful design and sizing of the rooftop solar plant

Alternative 2 – A battery-backed grid-interactive solar plant that only supplies specific loads such as lighting, but can support these loads without interruption even at night. This is suitable for factories that operate during night hours, or have critical loads that must work continuously without waiting for a DG to start

- Hybrid inverter –In addition to the other functionality described above, hybrid inverters also incorporate charge controllers to regulate battery charging

- Battery backup –A battery bank can be used which will be charged by solar power, and will support critical loads for short durations during the daytime when solar output may be reduced; and at night time during power failure. Lighting can be supported by solar with batteries this way, as can other light loads such as other production accessories.

- Battery sizing decides the duration of battery backup available. Batteries add significantly to the cost of the project, need to be replaced every few years, require maintenance, and impose weight and space requirements. Therefore we recommend considering both current and future cost and space requirements before deciding on the size of the battery bank

- Powering critical loads –When combined with a battery bank, a solar plant can be used to reliably support critical loads.

Takeaways

- Solar energy (both thermal and PV) can be used to supply the electricity and heat requirements of a factory

- Rooftop solar PV can meet up to 10 to 15% of a factory’s electricity requirements in India

- Solar thermal devices can be employed for various industrial processes and HVAC applications that require heat as input

- If your factory consumes a lot of diesel for power generation, rooftop solar can abate up to 10% of your diesel bills, subject to timing of load shedding

- 100 SF of shade-free rooftop space can accommodate 1 KW of rooftop panels and hence provide 4 kWh of solar power per day, on average

- Solar power costs Rs. 4.5-5/kWh or less, compared to Rs. 18/kWh or more for diesel power

- Cost of solar power is fixed for the next 25 years, whereas diesel cost keeps increasing

- As your rooftop space may not permit a solar plant large enough to power your entire load, your solar plant may need to integrate with your diesel generator

- Integrating a solar plant with a diesel generator requires careful design and sizing of your solar plant with respect to your diesel generator

- Solar power combined with a battery backup can be used to ensure that critical loads are kept running even during load shedding

- As batteries are quite expensive, we recommend limiting the backup duration to an hour, subject to specific needs at your site.

Skip to content

Skip to content