OK, so you already know the stuff that’s presented above.

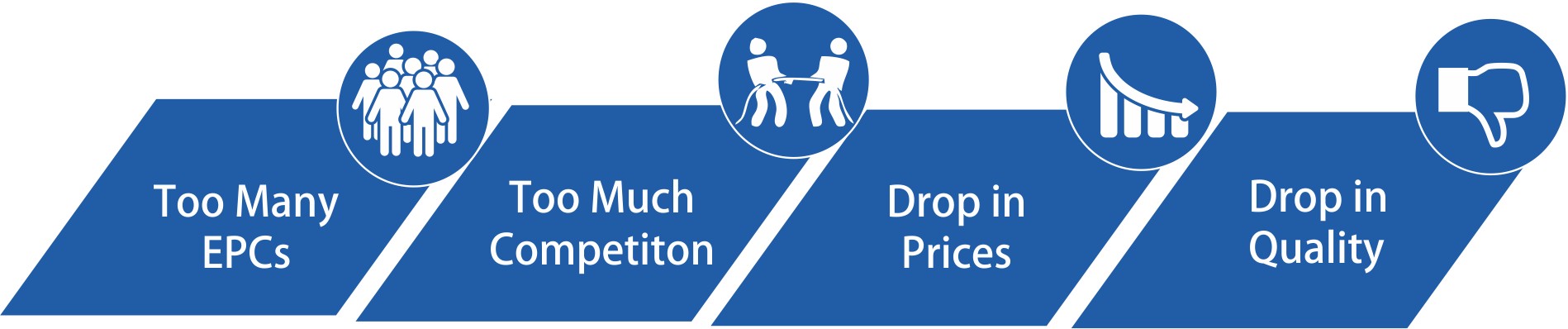

You have already read or heard about the fact that there are EPCs, and there are EPCs.

Given that it is well known that there are a number of rather average EPCs out there who could seriously harm your solar power plant investment, I find it intriguing that many developers still end up choosing EPCs with not a lot more care than they would choose their fruits and vegetables. And actually, in some cases, they exercise more caution while choosing their veggies and fruits!

Why is this happening? Surely the developers and investors are smart cookies who appreciate the importance of EPCs?

Yes, they indeed do – most solar power developers indeed are smart guys. I have come to believe the reason for the poor choices many times has to do with the inability on the part of the developer to apply simple but effective benchmarks, metrics and standards while selecting EPCs. Without such metrics and standards, selecting the right EPC becomes almost a game of chance.

And this challenge especially affects the small developers (less than 10 MW) and those developers who do not have much of a background in the solar power plant sector.

Allow me to explain.

The challenge of selecting the right EPC is not much of a challenge for large power plant developers. If you happen to be a developer putting up large scale solar power plants (20 MW and above), you have the luxury of selecting a brand name EPC, who will do a reasonably good job, in the very least.

The problem of EPC selection is acute for developers of small MW solar power plants (1-5 MW, specifically and to a certain extent, up to 10 MW). The reason is simple: Top, brand name EPCs might not be interested in serving this market, and hence the developer has to necessarily look for smaller EPCs.

And this is nub of the problem; while there is a good number of small EPCs in the market, it is not easy to know who is good and who is not, as very few of these small EPCs have much of a history behind them. In fact, if you leave out the top 5 EPCs, most others have done less than 50 MW, with a significant number of EPCs having done just 10 MW or less. Even among the work they have done, a significant portion could be contract work for specific portions of the power plant – just the civil or electrical work alone, for instance.

With this background, a developer, unable to differentiate between the EPCs on quality or credibility, hence ends up choosing on the only metric he can apply: cost. And ends up choosing the EPC with the lowest cost.

Well, an upfront savings of 30-40 lakhs/MW does sound too enticing to refuse, doesn’t it?

It does. And this post is to show developers

==> show developers why this supposed saving is grossly misleading,

==> provide insights on lesser-known aspects on which a good EPC can make a difference, and finally

==> Give them practical inputs of how they can go about choosing their EPC for optimum performance

The myth of upfront savings

As mentioned before, an average EPC can try convincing you that with small tweaks to quality, he can provide you with a capital cost that is 30 lacs/MW lower than what a good EPC quotes.

These savings appear considerable. But not if you compare these savings with the likely losses you will suffer over the next 25 years. Losses that happen because the EPC quoting a very low price could have made a number of compromises in order to accommodate the low price.

Solar Mango has encountered plenty of instances where developers went through with an EPC that quoted low and eventually ended paying the price for it with a significant decrease in solar power plant output.

We have encountered cases where where just 6 months into production, there have been cases of corrosion in some of the mounting structures resulting in some of the arrays simply not being upright any longer! These alone resulted in a decrease in annual output of about 2 lakhs/MW for the power plant.

In the case of sub-optimal mounting structures, what had happened was that, the EPC had compromised on the design of mounting structures. Instead of having a thickness of at least 80 micron for the galvanized structure, they had reduced it to probably 60 microns. In addition, in this case, the EPC had put in some rather mediocre DC monitoring systems, which could not detect some shading losses.

For this case, these two compromises ended up reducing the output by 2 lakh units per year. The developer in this case had probably saved 30 on the capital cost, but compare these savings to the loss:

| Parameters | X |

| Initial cost savings | 30 |

| Losses in the 1st year (2 lakh units loss @ a tariff of Rs 7/kWh) | 14 |

| Approximate losses over a 25 year period | 350 |

The losses mentioned in the above table could be much higher if one takes into account additional damages that could have happened in further years owing to other compromises during design and construction.

So, consider two EPCs:

- EPC 1: One offers you an initial saving of Rs 30 lac but a lifetime loss of over Rs 350 lacs

- EPC 2: The second quotes a price that is just right, but you get an additional Rs 350 lacs during the project lifetime. Even if you consider just the first 10 years, as 25 years is too long a period for your temperament, you get an additional 140 lakhs for an extra unfront expense of Rs 30 lakhs (or less)!

Essentially, for saving a few tens of lakhs, the developer has incurred a loss of over 10 times that by going with EPC 1.

A fair question could pop up in your mind – What is it that EPC 2 could be doing that will make the solar power plant far better than that constructed by EPC 1, without significantly increasing the costs?

Take Help from Experts @ Solar Mango

Talk to Ramya @ 9489339903, ramya@solarmango.com

Click here to know more

At Solar Mango, we had analyzed various EPCs, especially their work at the design stage, and listed some of the best practices that the top quality EPCs bring to the table. Interestingly, some of these practices even give rise to cost decreases, which implies that you could actually have a pretty competitively priced solar power plant, and even the upfront savings between a well executed power plant and a poorly executed one with quality compromises might not be as high as Rs 30 lakhs!

So, what indeed are these best of breed practices?

Let us look at some aspects where average EPCs do a, well, average job, and also how these could be done much better without costing you a packet:

- DC Sizing

- DC Side SCADA Monitoring

- Shading Losses Due to Inefficiency PV Panel Layout

- Corrosion in Mounting Structures

- Sub-optimal Cable Sizing

- Degree of Customization

- Ensuring Presence at Factory During Production

- Sub-contracting at Various Levels

DC Sizing

Say you get a PPA allocation of 2 MW. What should be the DC sizing for the plant? Should it be be 2.3 MW DC or 2.1 MW DC or something else? An excellent EPC gets this right for the developer by analyzing not just the technical side but also the commercial side to get the best revenues at reduced costs.

By commercial side, I mean due consideration to the state regulations. There are instances in states like AP where beyond a CUF of 24% there won’t be any payment for units generated. So even if the DC design produces such high generation (say with the implementation of trackers), it wouldn’t benefit the developer.

DC-side SCADA Monitoring

The analytics & outputs at the DC side of the plant is an aspect that is missed out. The focus is mostly on monitoring at the inverter level. What about string level monitoring? Is this factored in by an ordinary EPC? Definitely not. And believe me, the DC side losses can be extreme.

For example: Just imagine 5 arrays of say 10 kW each has been disconnected and this had not been detected for a period of 10 days. The losses can amount to 50*4.5*10=2250 kWh. This alone could result a loss in revenue of about Rs 15000 (considering a tariff rate of Rs 7/kWh).

Shading Losses Due to Inefficient PV Panel Layout

Design flaws leading to shading losses account for 10-20% losses in a solar plant. Of course, there are situations where shading can’t be avoided. In such cases, the output is optimized by ensuring the same pattern of shading falls over the panels. This just reiterates the importance of spending quality time on the design layout which is often overlooked by second-grade EPCs.

In the case of trackers, it is crucial that the EPC coordinates with the tracker company to ensure that the panel spacing is in accordance with the tilt angle.

Corrosion in Mounting Structures

Although hot dip galvanized steel is what is specified by EPCs for mounting structures in their quotes, does this mean they are going to follow it while installation? This concern comes due to increasing happenings of corrosion even within 6 months into the operation of the power plant.

There are 2 aspects that are important here:

- A high quality galvanized structure should have a thickness of at least 80 microns.

- Ensure that the original structure which is to be galvanized is corrosion-free

Often, vendors who are sub-contracted the job of doing this can disregard providing this optimum thickness thereby causing unexpected structural failure.

Imagine a situation where you have to replace some of the mounting structures in your plant after 5 years. Even replacing 25% of the structures could cost anywhere from 10-15 lakhs.

My point is that an EPC must take the initiative of being physically present at the premises while the galvanization is done and catch any malpractice in the process.

Unacceptable Cable Sizing Methods

As the current in the wires increase, the cable thickness employed increases which in turn increases the cost of cables. EPCs forced to reduce costs find this as a convenient way to reduce costs.

Using Aluminum instead of Copper can reduce costs by even up to 8 lakhs/MW. But copper is a better conductor than Aluminum. Not that using Aluminum is bad but just that EPCs should not go over board and compromise future plant performance.

Degree of Customization an EPC can Bring

Customization is one feature that could define a good EPC. Lets assume you go for string inverters for your plant. And string inverters are usually placed below your panels so that there is sufficient shade. But since they are out in the open, rains could damage it. This is mitigated by providing a rain canopy over the string inverters. It’s such simple and innovative actions that make the difference.

Ensuring Presence at Factory during Production

Most EPCs are unwilling to be present at the module manufacturer’s factory to test the modules before they are despatched to the site, and to witness and evaluate EL tests, flash test, etc and for pre-shipment inspection to make sure that the BOM requested is what we get on-site

Additionally, there is a need verifying the modules at the sub-component level. Imagine you purchase your panels from a tier 1 manufacturer. A typical EPC does not take the effort to check the branding of the EVA, backsheet, glass etc. Going this extra mile could go a long way in ensuring plant integrity.

Sub-contracting Various Stages of SPP Construction

Sometimes when you sub-contract part of the civil work, you have to verify the background of the contractor. What if your contractor passes down the work to other contractors and in the end it goes down 3-4 layers? This kind of layering will only mean added costs for each contractor. Give the job to a specialist and let them take care of the rest.

It might be true that the reason for different kind of failures might be different for different cases, but the prime commonality to all of these is that: Developers compromised the quality of the installations in a desperate need to cut down the costs.

An error at the design stage is critical for the plant as if the design is wrong, then it doesn’t matter how good a component you are using. Losses are bound to happen.

In fact, we are aware of an occurrence where the annual generation amounted to a mere 9 lakhs/MW just because of shading losses due to sub-standard PV layout! This may be a one-off case from a poorly performing EPC but it definitely does mean that a careless EPC selection can have its repercussions.

Recommendations for choosing EPC

The scope of an EPC can range from site analysis & DPR preparation to the final inspection and commissioning of the plant. Some of these activities, if performed by a really good EPC, can make all the difference.

| Scope | Degree of difference that a really good EPC can make |

| Regulatory | Low |

| Site Analysis | Low |

| DPR | Low |

| Detailed Design & Engg | High |

| Procurement | High |

| Construction | High |

| Inspection & Commissioning | High |

| Insurance | Low |

As seen above, it is the set of activities pertaining to design, construction and procurement that weighs to be critical in the contribution by the EPC. An EPC that compromises the quality of design of the plant to make up for the cost reduction will only spell disaster for the developer.

In which areas does a really good EPC bring value addition?

| Parameter | Value Addition by a Really Good EPC |

| Capex |

|

| CUF |

|

| Degradation |

|

| Operations & Maintenance |

|

Summary

I have discussed a lot in this post, so allow me to summarise the following, especially valid for solar power developers putting up power plants in the range 1-10 MW and who might not have expertise in the solar power domain:

- As you would have already heard, it is a bad idea to choose an EPC mainly based on cost

- There are many small EPCs who offer you an excellent quality of solar power plants; they may not be as cheap as the poor quality EPCs, but the small additional cost pales into insignificance when you consider the benefits you get from a well designed and constructed power plant.

- There are a number of small aspects during the design and procurement stage that can make a big difference. It will be difficult if not impossible to correct these at the construction or post construction stages. Some examples of these “small” aspects are provided in this post.

- Some of these design tweaks might even result in significant cost savings to you even at the construction stage, implying that the total cost for a high quality EPC might actually approach that of a poor quality EPC

- Finally, it is worth your while to spend time with the EPC and what he does during design and construction. While you might not be technically capable of overviewing design aspects, the very fact that there is an oversight will ensure that the EPC does a better job than otherwise. Some smart developers are also choosing an external design & procurement management company to oversee this (Solar Mango, by the way offers this external Project Management assistance through its PMC+ Program)

Just remember this: By investing in the right EPC and by spending a few more lakhs overseeing what he does on your own or through an external expert, you save many crores over the 25 years period.

A few lakhs more expenses or a few crores of losses? – You decide

Skip to content

Skip to content

i am chief engineer -marine.with 24 yrs ship repairs (mechnical/electrical/audits/hsse/hr) wish to start up with solar power indusrties.pls advise suitable option with your guidence.or pls call

thanks/regards.

sunil satam,

9833175064

Thank you Sunil for your kind note. I will get someone from Solar Mango to discuss this with you

Thanks again

You have tried to list out many of the problems that happens to installations done by the EPC companies’s negligence (if I may put it so). The solar sector has exploded suddenly and as you have narrated, EPC companies have mushroomed. Unfortunately 90% of these companies do not understand the real Engineering behind EPC. For them it is just a labour supply and expect things to just fall in place.

As I see the major issues are because these EPC companies have not even heard of many activities like Design review, vendor assessment, Quality assurance in component supply, civil/electrical construction etc. They do not even try to adopt any standard methodologies in the activities they perform.

Many developers are trying out their hand first time in power projects and hence do not know of the standards and methodologies that need to be followed and hence are at the mercy of the “EPC companies”

It is here that the PMC comes in and people like us can offer this at a nominal cost. My company Greenew Technologies even go to the extent of offering the consultancy with a rider that we will ensure that our services will be “deemed as of no charges” (since we promise to make savings which is more than the amount we charge as consultancy).

Another aspect where the projects gets done up with inferior quality is the non attention given to supply chain management (the project site is always at emergency with delayed material receipt at site). This leads to getting work done hook-or-crook.

On the whole, it is because lack of process and procedure adoption that we have inferior EPCs. ( many so called EPC are not even aware of such methods).

I can give you a host of horror stories that happen due to above instances.

Thanks for bringing this subject up.

Thanks Radhakrishnan for your kind and detailed comment

I agree that the lack of a structured process is a critical challenge that deprives the solar power plants of the quality they deserve

It will be wonderful if you could share here some simple examples of processes that can be included. You see, while we might want the EPC vendors to use comprehensive processes, that might be asking for too much from small EPCs at this stage. However, surely there will be simple processes that can be adopted by most that alone can bring in significant benefits and quality improvements?

I will be glad if you could point out some here, and that could be a great way to take this analysis to the next stage

Many thanks once again for taking time to provide such detailed insights and guidance, all the best!

How do I find an EPC who will be flexible and listen to the developer/owner’s needs?

Dear Keerthi,

I think it is better to go for a smaller EPC which has stable operations if you expect them to be flexible. Most large EPCs do not take the extra effort to listen to each and every demand of the owner/developer. This is especially true if you are a small-time developer who wishes to put up a 1-5 MW plant.

Another step is probably to go for an EPC that is easily accessible by you. If issues crop up after project commissioning, the EPC shouldn’t be too far away to come and carry out any corrective measures.

Dear Sir

This is Senthil from Madurai

I have carefully read your recommendations above. All these will in fact lead to good quality plants, but will not some of them, such as ensuring we are present at the Chinese factory when the BoM is assembled will significantly increase costs of the power plant???

I look forward to your valuable inputs sir, thank you very much

Interesting post Mr Santhanam

What I find lacking in many EPCs is the design talent. Yes many of them are good at PVSyst etc., but only a few of them are willing to buckle down and try understanding the entire solar power plant concept in minute detail – something that is required if they have to optimize on every important aspect.

Some of the aspects you have mentioned – such as DC cable sizing – are hardly given any attention to by many EPCs. When i comes to inverter selection as well, many EPCs blindly go by thumbrules and select mostly central inverters for MW scale power plants, without giving any thought at all about string level monitoring, or monitoring at the combiner box level, thereby missing a lot of critical insights about the operation of the power plant at a more granular level.

I am glad once again that you chosen to write about this topic in detail

Thank you

Rajesh

To add to what Mr Rajesh said, there is a feeling that a lot can be improved with regard to the maintenance practices followed in solar power plants. This is a critical factor in maintaining the long-term working of the plant.

SCADA systems in many plants aren’t used as effectively as they should be. In fact, many of the maintenance personnel don;t even know how to use them. Many big companies develop plants just to avail the benefits associated with it. Such practices would only bring a bad name to the industry in the long run.

Nice way to summarize the real life problems of small developers. In fact, while aiming for cost reduction, they go for compromise on the quality and design of entire PV plant which result in lower generation, revenue, profitability and higher payback period.

Sir, I appriciate the efforts of thinking very precisely about the EPC classification . We are Electrical consultants at Pune, Maharashtra. We will be at pleasure to meet you and discuss the issues in near future. We will be glad if you permit us .

Thanks . Aniruddha Murgudkar ph.. 09922810205

Pingback: Super Big Resource on Solar Power Costs & Returns - Solar Mango – #1 guide for solar

Pingback: Solar Power Sector – PV Solar IPPs – The Intelligent Investor

Dear Sir,

I had a bad experience of so called Tier 1 Channel partners or EPC from Australia. It wasnt MW scale job but the companies were tier1 Chanel partners or so. Though they were very good on paper there were time overruns and they simply left our clients and us in lurch.We wish to give the best to our clients for their trust in us,but we lack design expertise.We are ready to outsource that ,but are skeptical of someone taking our project away. We want professionals who can do their part of job and we deliver as team in the best interest of clients. Being in energy efficiency field for long time we enjoy trust of clients which is sacrosanct.

In your post you should have given what should be done to become a good EPC by a startup who wishes to enter. Kindly share good practices if possible in my mail if possible.