Talk to most developers or EPCs and they will tell you that developing a solar power plant is really simple, with the power plant itself having few moving parts and with most of the components fairly well understood.

Is it really that simple to put up a solar power plant? Yes and No.

Yes, if all you wish is to put up a solar power plant that is just good enough.

No, if you wish to put up a great solar power plant.

A great solar power plant? Now, what on earth could that mean? And how could a great solar power plant be different from a good enough solar power plant? After all, isn’t a solar power plant just a bunch of panels strung together? How much innovation could be brought in to make a good solar power plant to a great solar power plant?

You will be surprised to know that a heck of a lot of innovation can be done. This detailed blog post will show you how.

[ By the way, Should you be interested in working with high quality firms to implement very high performing solar power plants, send a note to enquiry@solarmango.com with the Subject: High quality solar power plant.]

Description of the Plant

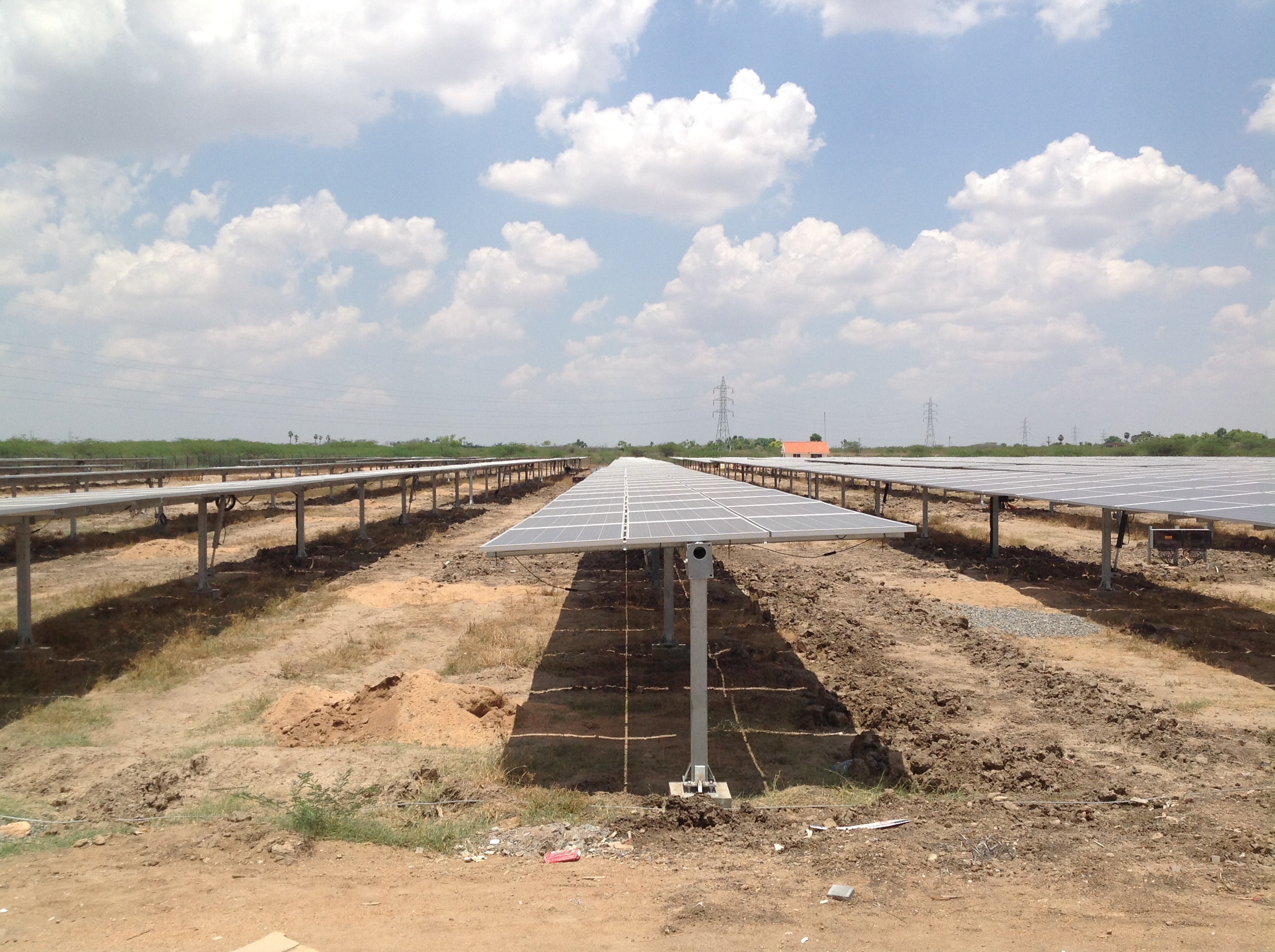

This blog post scrutinizes a 2 MW solar power plant developed and implemented by Ranergy Solutions, a system integrator based in Chennai. They are among the few system integrators who combine effective and timely implementation with a good dose of innovation.

The 2 MW plant, which comprises solar trackers, has been completed under the preferential tariff scheme by TANGEDCO.

Before we analyze why this solar power plant is superior quality, let’s take a look at the key stats and component specifications for the plant.

Key Stats

| Capacity | 2.3 MW DC, 2 MW AC |

| Capital Cost | Rs. 13 crores |

| Area | 12 acres |

| Location | Thiruchuzhi Village, Virudhunagar District, Tamil Nadu |

| Scheme Implemented under | Preferential Tariff Scheme – TANGEDCO |

| PPA Rate | Rs 7.01/unit |

Component Specifications

| Component | Make/Model | Nos |

| Solar Panels | Trina Solar – 315 Wp | 7296 |

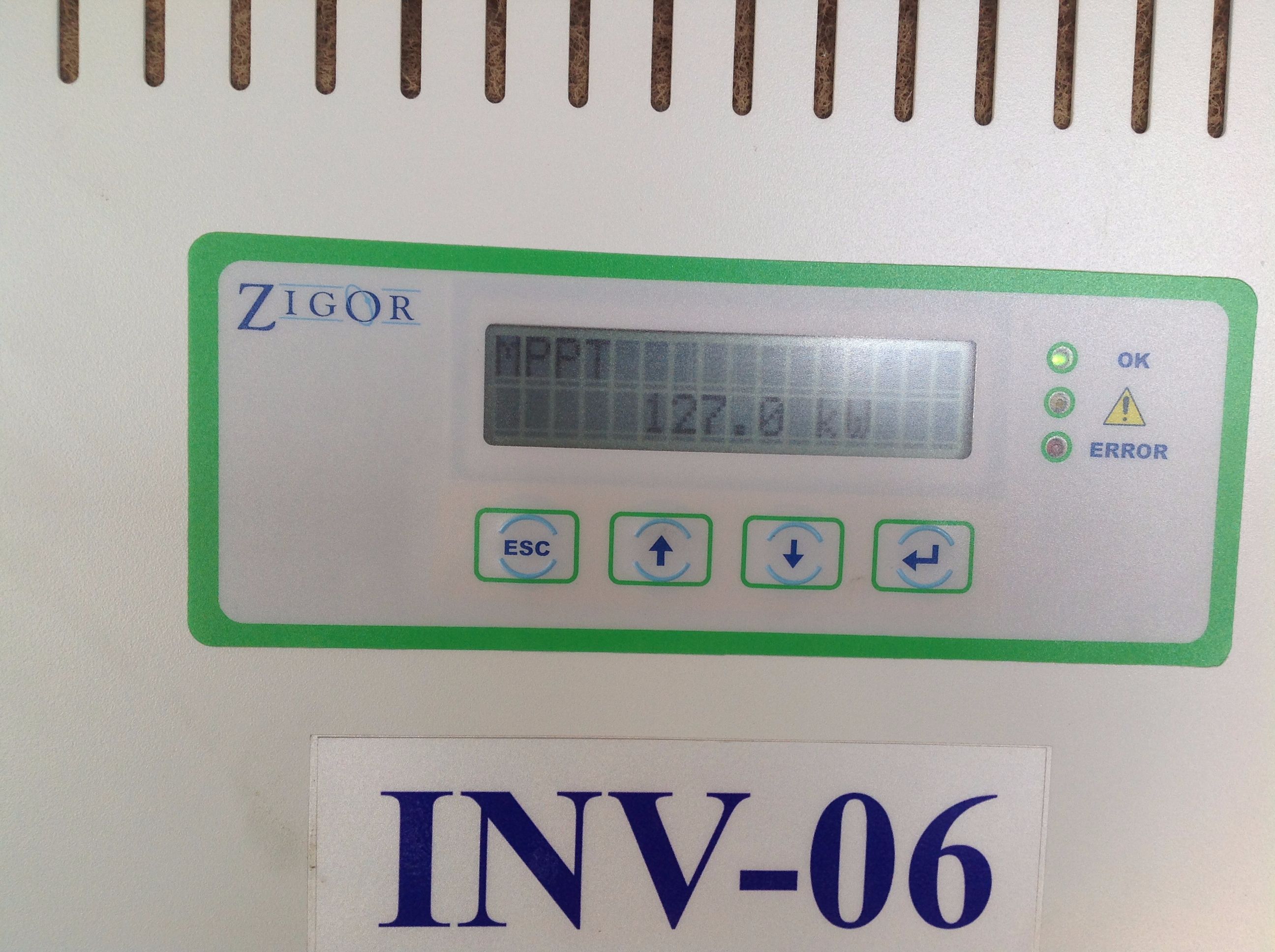

| Inverters | Zigor – 125 kW | 16 |

| Smart Combiner Boxes (AJBs) | Nordic | 16 |

| Trackers + Mounting Structures | Infinite Ercam | As required for a 2.3 MW DC plant |

| DC Cables | LAPP | As required for a 2.3 MW DC plant |

| AC Cables | Havells | As required for a 2.3 MW DC plant |

Wish to purchase high performing solar panels?

Talk to our Expert team – Send a note to sourcing@solarmango.com

A Superior Quality Solar Power Plant

Now, let us look at what could constitute a great solar power plant. Solar Mango defines a great solar Power Plant as follows:

- Maximum Power at Minimum Cost – A power plant that generates the maximum possible electricity during its lifetime (25 years) at the lowest possible cost Per kWh over the lifetime.

- Smooth Operations – A power plant that functions and buzzes along smoothly day in and day out for 365 days a year for 25 years, without giving any trouble at all to the developers.

- Transparent and Resilient – A power plant that is highly transparent and resilient – in that the owner can understand the performance of the power plant from wherever he or she is, and a power plant that can be up and running within the shortest possible time just in case of any issues that crop up at all.

Maximum Power at Minimum Cost

Based on the current generation data, the solar power plant is generating a bit more than 6.0 kWh/kW/day. Given that this was in May 2016 which is probably the third best month and not THE best month for solar generation, one can perhaps expect about 6.2 kWh/kW/day during the best month, and the developer expects an average of about 6 kWh/kW/day based on annual generation. This is more than 30% higher than what a good tracker-less system can be expected to generate at this location.

Three key components that go into maximizing power production of the plant are:

- Trackers

- Efficient & Elegant Design

- Optimal O&M

Trackers

Here, ensuring that you choose a very good tracker company that can provide you with not just a great quality product, but great support as well in the initial stages, when your plant is just about settling down.

Mounting Structures + Trackers

Ranergy chose to deploy tracking system from InfiniteERCAM, a subsidiary of Energia ERCAM, Spain, due to several unique characteristics and the proven global track record.

The trackers are controlled by Master – Slave controller combination. A total of two Master controllers and fifteen slave controllers have been deployed to control the entire 2.3 MW DC farm.

InfiniteERCAM trackers consist of individual rows of standalone trackers, thereby increasing the reliability of the solar farm. Each row of tracker comprises of 2 hydraulic actuators (cylinders). The hydraulic oil for the actuators are supplied from an oil sump attached to the hydraulic power pack. Each oil sump can accommodate 8 liters of hydraulic oil.

The automated actuation of the trackers is electrically controlled. If necessary, trackers can also be operated manually. The single axis trackers deployed follow the daily movement of the sun from east to west direction. The trackers and the rotation are custom programmed with an algorithm that incorporates the position of the sun and the tracker layout to ensure +/- 1° tracking accuracy and shadow free operations. Although 8 rows of trackers are connected to one control box, each row operates independent of the other.

Enhanced Trackers – Unique features and benefits of InfiniteERCAM trackers include:

Independent rows of trackers – with 63 panels (315 Wp each) per tracker (19.85 kw/tracker) – highest reliability in the industry

Configuration Flexibility – Highest in the industry. Individual rows that are not in a block allows deployment in land parcels with constraints

Two actuators per tracker– provides the most robust structural resistance to wind loads in the industry

Hydraulic actuation – Robust tracking mechanism that protects the trackers and panels by providing much required damping effects from vibratory wind loads

-55° to +55° daily tracking range – Most trackers used in the industry have an tracking range of -45° to +45°. InfiniteERCAM trackers deployed here goes an extra mile by providing a 22% increased tracking range resulting in much needed higher generations.

Foundations for the structures have a depth of 1.5m. – Low foundation costs

404 foundations per MW – least in the industry and least foundation costs

Tracker row spacing is 7.5m – most in the industry resulting in higher generation and yet provide the best land coverage ratios

In this case, the whole structural setup (mounting structures + trackers) is provided by Infinite Ercam with trackers of their own make and structure & other equipment sourced indigenously from their various trusted vendors.

| Ensuring that the entire procurement for the structural arrangement (structures + tracker) is managed by a single contractor eliminates any sort of confusion that might arise when multiple parties are involved, such as, incompatibility of MMS to trackers, alignment of panels, etc. |

Take a look at the following figures which show tracker orientations during different times of the day.

Fig. 1(a) Tracker Orientation at 9.30 am

Fig. 1(b) Tracker Orientation at 12.00 pm

Efficient Design

When you talk about an efficient design, it is not just the spacing of panels (solar panel layout), but also how well you would like the tracker to work, it is also about how much care you take about the choice of inverter, how well you are maintaining the inverters, how much care you take to ensure that cable losses are minimized.

Take a look at how Ranergy implemented an efficient, elegant design.

- Choice of Inverters

Ranergy opted for 125 kWp inverters from Zigor HK Ltd. When compared to a central inverter of 1 MW size, the 125 kWp inverters provide benefits of a string inverter at the cost of a central inverter. Some of the factors considered by Ranergy for choosing these inverters include:

- Cost reduction of DC cables

- 16 MPPTs compared to 2 MPPTs(in case of 2 nos of 1MW Central inverter) resulting in higher production

- Easily manageable size of inverters resulting in easier installation, commissioning and maintenance

- Reduced downtime: In case of issue with an inverter, only 125 kW is affected.

- Two spare inverters are maintained at site to reduce downtime

- Optimal Design and Placement of Inverters

The 16 inverters have been placed in 4 different inverter rooms which have been strategically located within the solar power plant to reduce the DC cable length. This provides for an elegant design and minimizes DC cable losses, which typically adds to a chunk of losses in the case of central inverters.

|

Having four inverter rooms instead of just one ensures that the average length of DC cable from the panels to the inverter is reduced. Given that DC losses are much higher per unit distance than are AC losses, having 4 inverter rooms placed around the power plant results in significantly lower electricity losses over the power plant’s lifetime. |

Apart from this, some of the other parameters that are given due consideration for the inverter design are:

- All the inverters are equipped with MPPT (Maximum Power Point Tracking). The purpose of MPPT is to maximize the power production by applying the optimal voltage and current for any given ambient conditions. The presence of 16 MPPT inverters enhances the power production and reliability of the plant.

- The inverter room temperature is maintained by exhaust fans which are controlled by the inverters themselves. The inverter room temperature has to be maintained below 45°C. Moreover, the inverter rooms are built with an inverted V roof which reduces the temperature by 5°C. The inverted V-roof was inspired by similar architecture in the adjacent villages in order to give a rural look and feel to the whole plant so that it blends well with the prevailing landscape.

Fig 2. Invertor Room (Notice the V-shaped roof and 4 exhaust fans)

- The warranty for the inverters has been extended to 8 years (instead of 5 years for a typical power plant) at a small additional cost. This was done as an extra risk mitigation measure. Given that a good inverter can be expected to function well for 12 years at least, I would reckon that an 8 year a warranty is a pretty good deal.

Optimal O&M

Solar power plants should not require a lot of maintenance, beyond the cleaning of panels at regular intervals. Even a solar power plant with trackers should not require much maintenance, apart from the regular monitoring if the trackers are performing OK (even this can be monitored remotely).

| It is pertinent to mention here that the data from the first few months of this Solar Power Plant are highly encouraging, with generation touching 6 kWh/kW/day, almost 30% higher than a tracker-less Power Plant and about 6% higher than what nearby Power Plants with trackers are generating. A significant difference when you think of what such a difference could make when repeated day after day for 365 days a year, and for 25 such years. |

Smooth Operations

- Good planning to ensure minimal O&M

- Robust infrastructure for O&M

Good planning to ensure minimal O&M

You can run a solar power plant with minimum staff if you do two things well:

One is to prevent the need for complicated maintenance by designing and implementing the power plant in a simple and elegant manner. Two, if you train well the minimal manpower at the power plant.

Some of the measures that were taken to reduce O&M are as follows:

- Effective Laying of Cables

Care is taken to ensure that the underground laying of cables adheres to safety standards. Typically, in cables are laid as follows:

| o Cables are placed within protective conduits

o Sand is poured below and above the cable conduits as a form of insulation and protective measure in the case of fires o An extra layer of bricks is added to help laborers identify the presence of cables underneath while digging operations are undertaken. o Mud is laid over the bricks and the land is leveled. |

- Due Diligence of Component Manufacturers

As an example, while Zigor is not a well-known inverter brand in India, the developer chose it after doing significant due diligence about the company and the inverter performance. It was also selected after direct interactions with the vendors and have already been tested in many rooftop installations deployed by Ranergy and proven to exhibit superior performance. Moreover, Zigor also has a support team in Chennai which is provides an edge as Ranergy operates from this city and could be called upon in the case of any maintenance issues.

Attention to such details could go a long way in ensuring cost-effective O&M.

- Conduits for DC Cables

Special FRPP conduits have been utilized to connect the DC cables from panels via array junction boxes to the inverters. Similar protective measures taken throughout the plant cost approximately 10 lakhs.

Fig 3 (a). Conduits for DC cables

Fig 3 (b). Conduits for DC cables

Fig 3 (b). Conduits for DC cables

- Dressing of Cables

Another important consideration is with regard to the dressing of cables. Improper routing and dressing of cables is bound to cause extra losses. So, Care was taken to make sure that the DC cables are not too tight or loose and does not come into contact with sharp edges or even surfaces that might increase the temperature of the cables.

Robust infrastructure for O&M

In terms of regular maintenance, solar power plants need mainly cleaning of the panels using water. While this might sound simple, it can be a fairly time consuming exercise. Consider this power plant in which over 7000 panels are used. Now, cleaning 7000 panels is no quick task, and unless a good design has been thought out and implemented for cleaning, the O&M personnel could end up spending twice the amount of time (and also perhaps twice the amount of water) in cleaning the panels.

Here, in order to facilitate the cleaning of panels, pipes are set up at regular intervals along the rows. Moreover, the water utilized for this purpose has been tested for various parameters like pH level, hardness etc. Except for the hardness, other parameters have been found to be appropriate for the purpose.

Wish to purchase high performing solar panels?

Talk to our Expert team – Send a note to sourcing@solarmango.com

Transparent & Resilient

A well done design diagram which is also shared with other experts before the commissioning and even after the commissioning, so that any minor flaws are taken care of at the earliest.

Two aspects that can make power plants far more transparent and resilient are:

- A robust monitoring system/SCADA

- Simple but Effective Methods to Control in Case of problems

Robust Monitoring System/SCADA

A SCADA monitoring system has been used for remote monitoring and communication of signals between different power plant components.

Typically, the SCADA system has data-logging facilities that comes as part of the inverters and to some extent junction boxes. For more information on data that can be gathered from the inverter, refer the References section.

Fig 4. Inverter Screen displaying various parameters

|

In this plant, care has been taken to gather inputs from inverters, string combines boxes, weather station and net meter. The weather station comprises pyranometer as well as instruments for measuring cell and ambient temperatures. This adds a high degree of reliability and ensures that under-performance of the plant is mitigated. The faulty panel or set of panels can be narrowed down to the string level by identifying the reduced power generation in a particular string. Like in this plant, which has 19 panels per string, it would be pretty straightforward to detect the faulty panel and replace it. |

Now, the power plant will use not just a simple monitoring system that provides details of how the panels are performing in terms of their output, it will also provide details of weather, temperature and soil conditions.

Draker Inc, a US-based solar monitoring vendor, has supplied the SCADA system for the plant. According to the developer, Draker Inc, due to their superior data analysis capability (especially performance ratio, soil losses, etc), provide better performance in comparison with other vendors. Draker performs this by sourcing intelligence directly from panels. Depending on the extent of sophistication, they cost around 5-10 lakhs/MW.

Effective Methods for Control

- Cloud or Web based reporting system for those managing the power plant, which can also send alerts to the developers and other stakeholders if there is any trouble.

Other Observations

This section provides interesting observations that were made during the SPP visit.

- Generation during cloud cover: During a cloud cover, a drastic decrease in solar generation is observed. While a peak generation of 127 kW is observed on the inverter screen mid-noon, a temporary cloud cover reduced the power generated to as low as 25 kW. This represents an 80% decrease in generation during a cloud cover. There was also an instance where the power generated reached 130 kW due to the positive tolerance rating.

- Ability to withstand wind speeds: Although the typical rated wind speed is 150 km/hour for the structure, the panel frame made of Aluminum can withstand only up to 50 km/hour. Due to this, the panels are automatically brought to a horizontal position at high wind speeds.

- Exact Orientation of Foundations: The developer went the extra mile in ensuring that each row of panels has their foundations aligned in the exact north-south direction. This required the presence of a surveyor. Moreover, measures are put in place to make sure that the distance between adjoining pillars in a row is 6 m. The allowed tolerance limit was a mere 1 mm.

Fig 5. True N-S Direction

Summary

Overall, I should say that this solar power plant implementation has been quite impressive. The generation data from the first few months seem to really rewarding the high quality efforts put in by the developer.

Solar Mango will continue reviewing this power plant and update you on further improvements that the developer makes.

Should you be interested in working with Ranergy and similar high quality firms to implement very high performing solar power plants, send a note to enquiry@solarmango.com with the Subject: High quality solar power plant.

References

Inverter Monitoring System

Some of the typical parameters and values that are displayed as part of the inverter monitoring system:

- PV Input (DC)

- Cabinet Temperature

- Room Temperature

- Active Power

- Apparent Power

- Reactive Power

- Power Factor

- Active Energy

- Power Grid

- Inductive Reactive Energy

- Capacity Reactive Energy

- Voltage

- MPPT

Solar Mango conducted an interview with Mr. V. M. K Gopal, the Founder and President of Ranergy Solutions Private Ltd, in which he talks about his background & experience, motivations, innovations made during solar power plant implementation and take on government policies.

- Tell us briefly about your education and professional background.

I have a Bachelor’s degree in Electrical and Electronic Engineering from College of Engg, Guindy, Chennai. I also completed my MS (Comp Sci) from University of South Florida, Tampa, USA, before pursuing MBA from Virginia Tech, USA.

- As you are mainly a solar power plant EPC and solution provider, what got you interested in implementing your own solar power plant?

We are positioning ourselves as a boutique EPC for sizes in the range of 50kW to 10MW. We wanted to build our own solar power plant that we can showcase to our potential clients to give them a glimpse of our capabilities and quality of execution. This will also serve as a test bed for us to try different designs and frugal innovative technologies.

- While you have done a number of innovations in your 2 MW solar power plant, which of these, in your opinion are the most critical and productive?

In my opinion, going in with a 125 kW inverter in lieu of a 1 MW Central Inverter was a critical decision which I am sure will prove to be a productive decision over the life of the plant. Practically, all the small, slightly not-normal configurations we have adapted (including Wi-Fi communication from all equipment monitored for our DC monitoring solution), in tandem will produce the desired plant productivity.

- What are the future additions and improvements that you plan to incorporate in the solar power plant?

One innovative addition we plan on implementing is a water-less cleaning solution for the solar panels.

We also plan to fine tune our monitoring solution, analyze the correlations between the data and events recorded and possibly reduce the amount of losses (DC/AC cable losses, mismatch losses, soiling, etc.) as much as possible.

Moreover, a complementary, non-solar activity at the project site that will generate revenue to take care of Solar Plant Maintenance expenses is also being implemented.

- What is your wish list for our governments – central and state – in order that solar power, especially distributed solar power grows much faster?

Firstly, I would prefer implementation of Central and State level policies that are synchronized and harmonious.

Secondly, policies that encourage Solar power installations of smaller sizes as well and not just the utility scale MW power projects.

Lastly, the firm implementation of policies with proper checks and balances built in is also necessary.

To Avail the Premium EPC Services of Ranergy, please contact Mr. Nikhil.

Ph: 9940617877

Email: nikhil@solarmango.com

Website: http://ranergy.com/

Skip to content

Skip to content