Sweet Answer from Solar Mango: (updated Jul 2015)

An interesting question that is often asked of Solar Mango is on the value addition at each stage of the solar PV value chain – from polysilicon to module. We provide a brief insight on this below.

Broadly, there are four stages in the crystalline silicon module making process

PV Value Chain – Value Addition by Manufacturing Stage

Source: Greentech Media, 2013 (https://www.greentechmedia.com/articles/read/New-6M-Kerfless-Silicon-PV-Wafer-Fab-for-1366-Technologies )

Source: Greentech Media, 2013 (https://www.greentechmedia.com/articles/read/New-6M-Kerfless-Silicon-PV-Wafer-Fab-for-1366-Technologies )

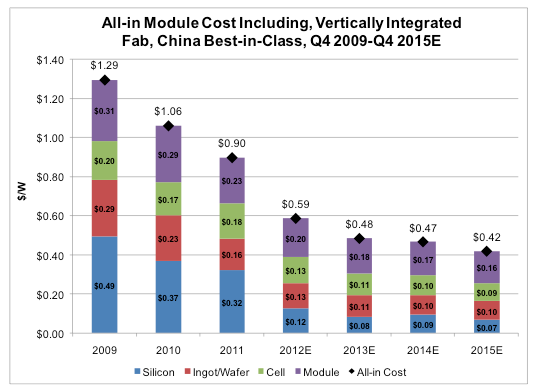

We can see from the chart that the value addition in each stage is now approximately the same, though historically (prior to 2012) silicon processing added measurably more value than other stages. This is mainly because the cost of polysilicon was much higher before 2012 than it is now.

Currently, the costs for making ingots/wafers and cells are about the same, per W.

Currently, most value is added at the module level. Even though the module making itself is just an assembly operation, the reason for such high value added in this stage is that this is the stage where all the components are brought together and assembled into one module. Thus, it is in this stage that the glass, aluminium frame, EVA and backsheet make their appearance.

Related Articles

- Silicon Wafer – The Chip that is Healthy and Gives You Power

- Polysilicon – from Sand to Solar Cells, it Starts Here

- Solar Cell – The Basic Unit of a Solar Power Plant

- How much does a rooftop solar PV system cost?

Ask Solar Mango

Have a solar energy related question to be answered at Solar Mango? Send it to ask@solarmango.com

Skip to content

Skip to content