Themes in this post: Solar PV value chain | Upstream manufacturing | Solar cell & panel makers | Solar panel component makers | Balance of system makers | Vertically integrated companies

Way back in 2010, I was asked to speak at a renewable energy conference in Chennai. The speaker just before me presented some wonderful slides not just on India’s solar power prospects but also on solar cells and panels, and the technology behind their manufacturing. I was getting quite nervous – here I was, having only a fairly preliminary understanding of the solar power sector, and I was going to speak right after an expert. I’m not sure how well my speech came through – thankfully, they had not recorded it and published it for posterity to gleeful witness to my ignorance – but right after our session, I made sure I caught up with the fellow who spoke before me, and we became friends who had kept in touch with each other – even if patchily – ever since. Kolan Saravanan was at that time in a senior position at Applied Materials, a company that made the machines and technologies to fabricate the solar cells. (He has since moved on to head the Indian operations of Centrotherm, a global leader in solar manufacturing solutions and technologies).

The meeting with Kolan was my first real professional brush with solar power sector manufacturing.

Just looking at solar panels might make one think that it should be rather easy to make them. But the entire process that results in being shipped out of factories is quite complex, with some of the upstream stage requiring quite high-end and highly capital intensive technologies.

In addition, while solar panels are the most visible among all components, they form only about 30% of the value of a solar power plant. There are other prominent components in a solar power plant that include solar panel mounting structures, inverters, monitoring systems, and electricals such as junction boxes, cables and wires.

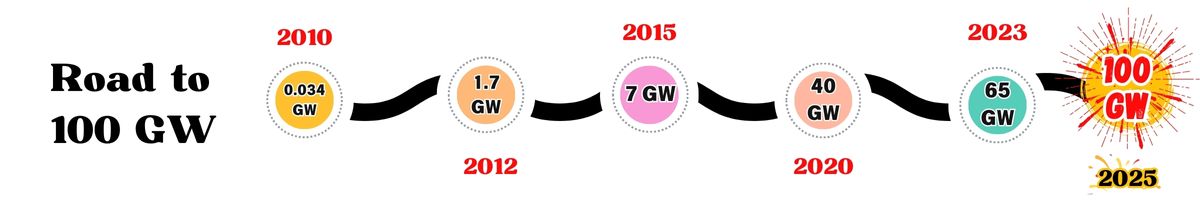

From the time the solar power sector in India started gaining momentum from 2010, most focus & efforts from both the government & business stakeholders have been in installing solar power plants, and thus on developers.

Until a few years back, the government turned a lazy eye to the sources of the solar cells, panels and inverters. The general vibe was – let the developers get the most economical components so they could generate power at the lowest possible price.

Solar PV manufacturing, in short, got ignored. This attitude appears to be changing.

The solar PV value chain

For such simple looking solar panels, solar photovoltaics has a surprisingly long value chain.

The whole process starts with quartz sand, which is then purified to extract silicon. This silicon in turn is pur through a set of processes that results in a silicon wafer, which is fabricated further to make a solar cell. The solar cell is the basic electricity generating unit of a solar power plant. Solar cells are assembled together along with the necessary electrical circuits to form solar panels.

#HQuartz -> Silicon -> Polysilicon -> Ingots -> Wafers -> Cells -> Panels#H

As you can see, it is a pretty long distance from the time quartz is collected until you get the solar panel.

Upstream manufacturing

The upstream portion of this manufacturing value chain (polysilicon, ingot and wafer manufacturing) comprises a number of thermal, material and mechanical processes that ultimately result in the silicon wafers that go into making solar cells.

As of Jan 2025, #HIndia doesn’t produce polysilicon, ingots or wafers#H at a commercial scale, though this status could soon change with some planned investments in upstream manufacturing. India has about a dozen companies making solar cells, and hundreds of companies making solar panels.

Solar cell & panel makers

Wafers obtained from the upstream process are fabricated into cells, and the cells are then assembled into panels.

Solar cell production facilities are typically fabrication facilities requiring clean rooms and high end fab machinery. Solar panel making is an assembly process, significantly low-end in sophistication and capital costs compared to the rest of the value chain.

Until about 2010, India’s solar cell and module making sector was small, and had just a handful of prominent players with high ambitions

Even until about 2017, you cannot say that Indian solar manufacturing was going anywhere. But post COVID, there has been significant activity in the Indian solar manufacturing scene – especially for cells and modules. Mind you, we are still very far behind China, but now, one can finally see the big aspirations and intentions being put into action.

Some of the prominent players in the solar cell and module production sector include Tata Power Solar, Adani Green, Vikram Solar, Waaree Energies.

Solar panel component makers

In addition to the solar cells and the circuit materials needed, solar panels also need a glass covering on top, aluminium frames to support the glass, an encapsulant that forms the back of the solar cell and finally a backsheet that forms the final layer on the back of a solar panel.

Glass – Prominent makers of solar panel glass in India include Borosil, Saint Gobain, Vishaka, Triveni and Gold Plus Glass.

Aluminium Frame – Some prominent companies making Aluminium frames for solar panels include Gujarat Aluminium Extrusions, Vishakha Renewables, Maheshwari Co, Kesri Metal Ltd and Padmawati Extrusions.

EVA & Backsheet – Prominent companies producing solar panel backsheet in India include Knack Energy, RenewSys India, Navitas Solar, Solar Specialty & Mitsui Chemicals

Cables & Wires – Prominent companies making cables and wires for panels and solar power plants include Polycab India, Finolex Cables, RPG Cables, Havells India and KEI Industries.

Solar power plant balance of systems

While solar panels form the power generation unit, a solar power plant needs many other equipment to complete the circle. These are collectively called the balance of systems, and comprise mainly mounting structures & trackers, inverters & monitoring systems, junction boxes and electric wires and cables.

Mounting structures are the support mechanism on which the solar panels are placed. These could be fixed structures or those that could be moved to face the sun at all times through trackers.

Inverters convert the DC power generated by the power plant to AC power, which is then fed to the transformer (if exported to grid) or to the main board if the power is consumed on the premises. Monitoring systems continuously monitor and analyse the power generation from the various panels of a solar power plant.

Electricals such junction boxes and cables perform their tasks that they do anywhere else!

I’m providing a list of prominent Indian manufacturers for the following, so you get an idea:

- Solar mounting structures

- Solar inverters

- Junction boxes

Mounting structures: Some prominent solar mounting structure firms include Pennar, Ganges International, Strolar, Neuvosol and MetalKraft.

Solar inverters: Prominent solar inverter makers in India include Sungrow, TMEIC, ABB (now Hitachi), Fronius & Delta Electronics.

Junction boxes: Prominent companies making junction boxes include Schneider Electric, Havells India and Lapp Group and DhaSH PV.

Vertically integrated solar power companies

Some large business houses and conglomerates are present in many parts of the solar power value chain, with prominent contributions as both developers and installers.

A case in point is the Tata Group.

The Tata Group, through many of its companies, is a prominent player in most value chain components. (Reliance and Adani groups might also belong to this exalted category in five years from now!)

The Tata Group’s power solutions divisions comprise an integrated solar player in manufacturing and EPC.

In manufacturing, a group company divisions produces high-quality solar photovoltaic cells and modules. A joint venture (Tata BlueScope) makes solar module mounting structures.

Tata Power Solar undertakes large-scale rooftop and ground-mounted solar projects for commercial, industrial, and utility clients, and in addition offer solar water pumps, home solar kits, and operate in solar rooftop segments.

Tata Power Renewable Energy Limited, a wholly-owned subsidiary of Tata Power develops, owns, and operates grid-connected solar power projects. It implements large solar farms across India, providing solar power to distribution companies, commercial entities, and industrial clients through PPAs.

The group’s presence in the solar power value chain goes well beyond installation & development.

Tata Cleantech Capital provides finance for renewable energy projects, including solar installations, offering end-to-end solutions from concept to commissioning.

Tata Projects Limited is an infrastructure and EPC arm of the Tata Group that often undertakes large turnkey contracts, including those in the power and renewable energy sectors.

Tata Consulting Engineers, a multidisciplinary engineering consultancy, provides advisory, design, feasibility studies, and project management consultancy services for solar PV plants—both utility-scale and rooftop.

Tata Motors, Tata Steel, and a few other Tata companies, while not direct stakeholders in the solar power sector, are consumers of solar power and integrate solar energy into their operations to meet sustainability targets and reduce energy costs.

Skip to content

Skip to content